engineering design office

quality management system according to ISO 9001:2015

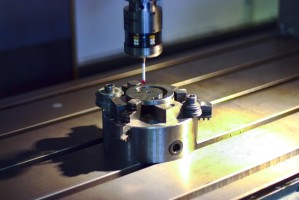

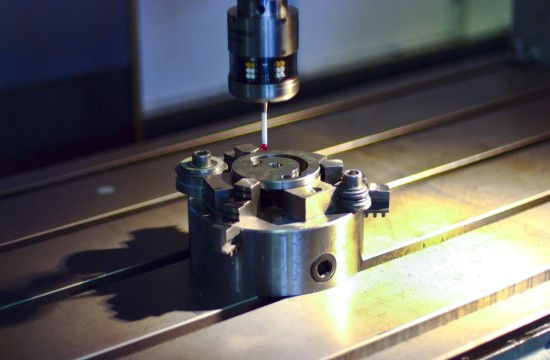

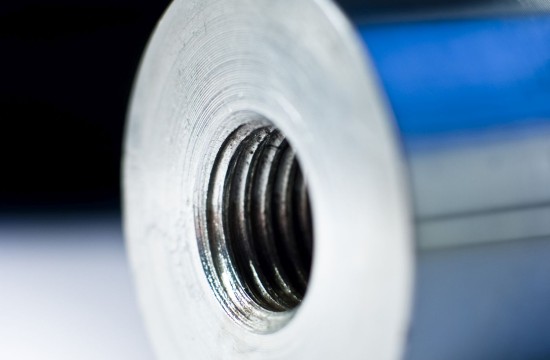

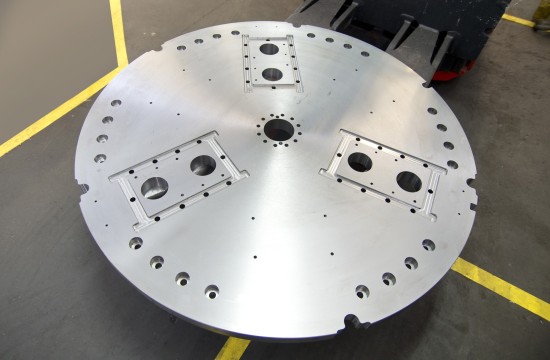

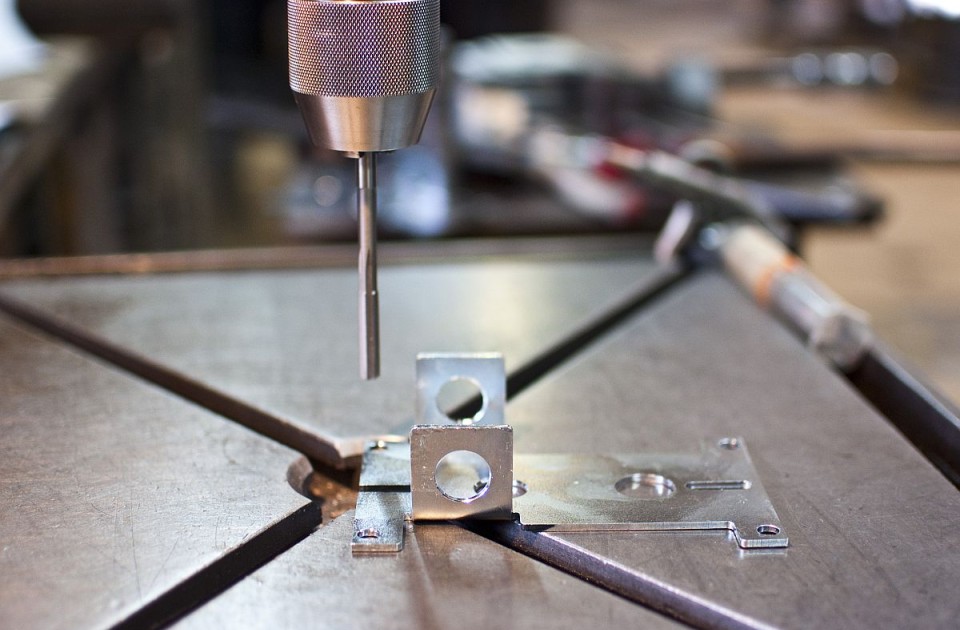

precision CNC and conventional machines

team of experienced specialists

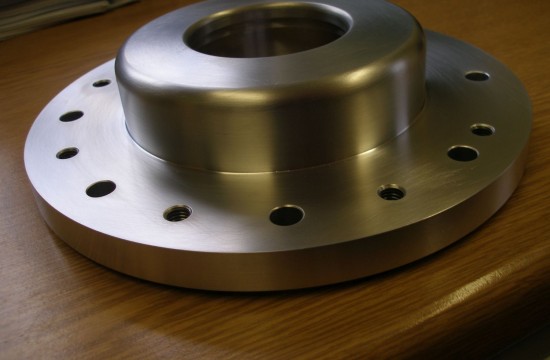

products for various industries

Range of service

What can we do for you?

Contact us

zapytanie@sordrew.pl