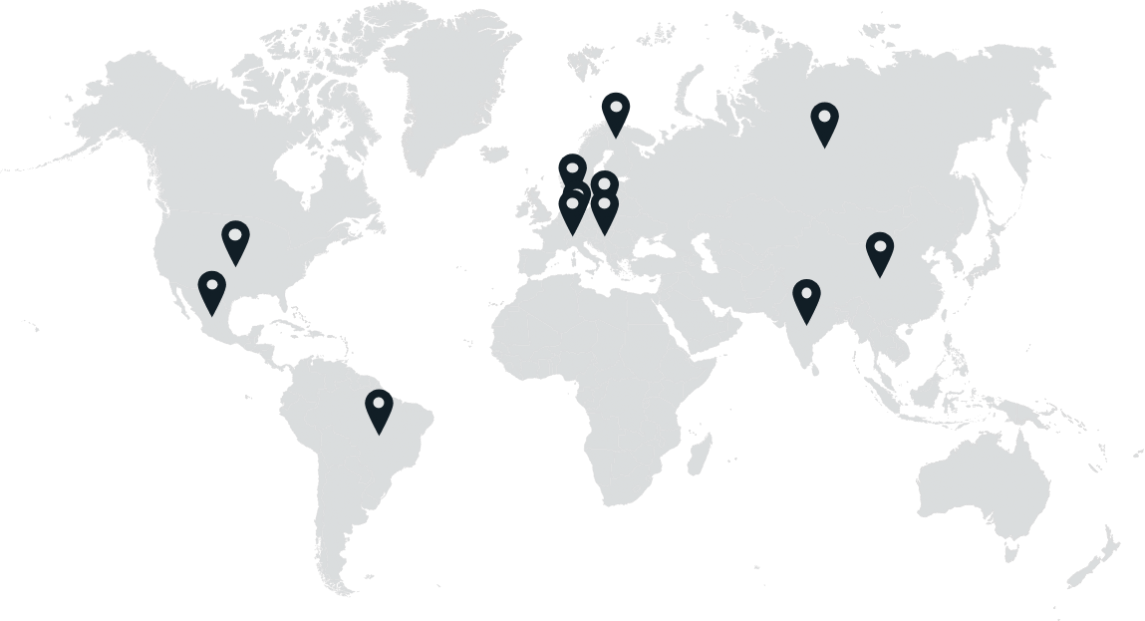

Areas of activity

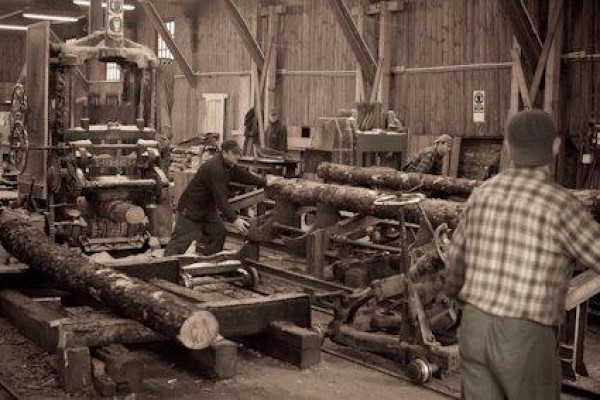

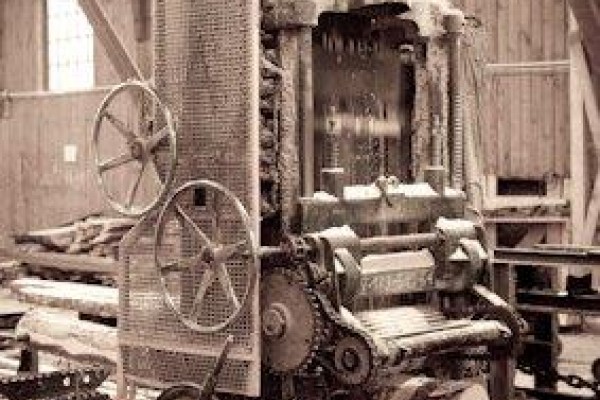

Wood

We create high-quality industrial wooden packaging while in our sawmill we produce sawn timber and structural wood. We also build ecological prefabricated houses.

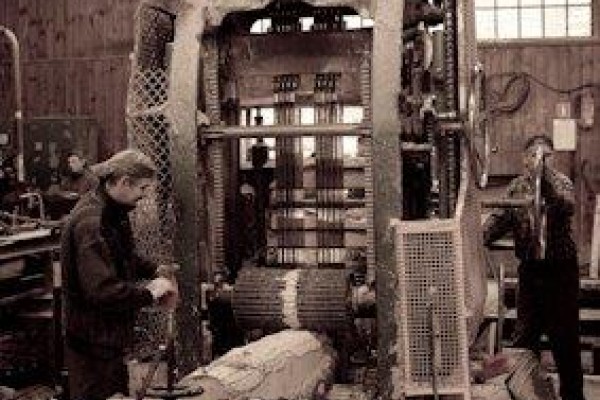

Metal

We specialize in the machining of metal parts. We also produce welded constructions of different levels of complexity.

Plastics

We provide professional thermoforming and die-cutting services of products made from all kinds of plastics for companies from various industries.